Best Practices for Electrical Wiring in New Commercial Constructions

Planning is the cornerstone of any successful commercial electrical wiring project. In the initial stages, detailed blueprints and load calculations are critical to ensuring the entire system meets both the functional requirements and safety standards. By carefully mapping out the wiring infrastructure, businesses can avoid costly rework and improve overall efficiency. Attention to future needs, such as scalability for technological advancements, is also a vital aspect of the planning phase, making the project adaptable to growth or upgrades.

Material selection plays a crucial role in the durability and safety of commercial wiring systems. Premium-grade copper and aluminum wiring, known for their conductivity and resistance to corrosion, are frequently used. Additionally, high-quality insulation materials such as PVC or cross-linked polyethylene offer robust protection against wear and environmental factors. These materials contribute to long-lasting performance, reducing maintenance costs over time.

Compliance with local building codes is a fundamental aspect of electrical installation. Licensed electricians rely on a combination of experience and rigorous adherence to standards such as the National Electrical Code (NEC) to ensure all installations meet legal and safety requirements. Regular inspections and detailed documentation are used to validate compliance at every stage of the process.

Commercial projects often face unique challenges, such as the complexity of integrating modern technologies, tight deadlines, and unpredictable site conditions. Addressing these issues requires flexibility, thorough preparation, and collaboration among all stakeholders. By implementing advanced project management practices and relying on skilled professionals, these hurdles can be efficiently overcome.

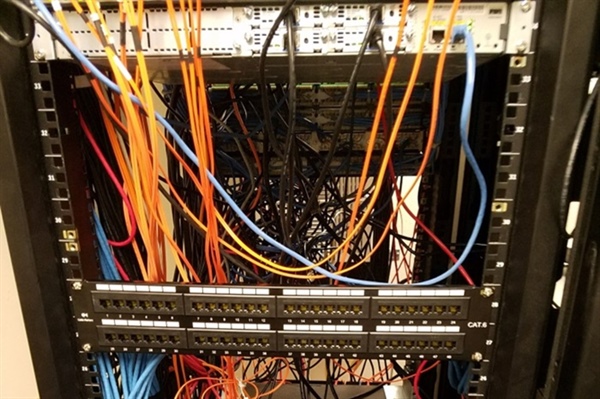

Future-proofing electrical systems is an essential consideration for businesses aiming to adapt to technological advancements. Structured cabling solutions, flexible load management systems, and provisions for renewable energy sources ensure that today's installations can support tomorrow's innovations. Thoughtful planning and the use of cutting-edge technologies are crucial in creating wiring systems ready for emerging trends.

How Does the Planning Phase Influence the Efficiency of Electrical Wiring?

The planning phase is critical in determining the efficiency of electrical wiring systems. Detailed load calculations, spatial analysis, and adherence to safety protocols ensure that the system is both functional and scalable. Planning also minimizes wastage, reduces installation time, and addresses potential challenges early in the project lifecycle.

In commercial projects, the planning stage involves collaboration among architects, engineers, and electrical contractors to create a wiring layout that seamlessly integrates with the building’s design. Advanced tools like CAD software are often employed to visualize and optimize wiring pathways. This meticulous approach ensures the smooth execution of the wiring project.

By prioritizing planning, businesses can avoid disruptions, costly changes, and compliance issues. For additional insights on comprehensive planning practices, visit commercial electrical services.

What Materials Are Recommended for Durable and Safe Commercial Wiring?

Durability and safety in commercial wiring systems rely heavily on the choice of materials. Copper and aluminum conductors are widely used due to their excellent conductivity and longevity. Copper, in particular, is favored for its resistance to oxidation and high current-carrying capacity, making it a reliable choice for heavy-duty applications.

Insulation is another critical factor. Materials like PVC (Polyvinyl Chloride) and XLPE (Cross-linked Polyethylene) are preferred for their heat resistance and durability. They protect the wiring from environmental factors and mechanical damage, ensuring long-term performance. For high-voltage applications, specialized materials such as ethylene propylene rubber (EPR) provide superior safety and insulation.

Accessories like junction boxes, conduits, and connectors made from corrosion-resistant materials add to the system's overall safety and functionality. For a full list of materials and their applications, refer to our electrical services.

How Do Electricians Ensure Compliance With Local Building Codes During Installation?

Compliance with local building codes is ensured through rigorous adherence to regulations such as the National Electrical Code (NEC) and regional amendments. Licensed electricians follow these standards to guarantee the safety and legality of their installations.

Inspections are an integral part of this process. Before, during, and after installation, electricians work with building inspectors to verify that all work aligns with the required codes. Documentation, including permits and wiring diagrams, supports this compliance and ensures transparency.

Training and certification also play a vital role. Professional electricians stay updated on code changes and advancements in the industry to provide compliant and safe installations in every project.

What Are the Common Challenges Faced During Wiring Installations in Commercial Projects?

Commercial wiring installations often encounter challenges such as complex building layouts, tight deadlines, and integration of modern technologies. Navigating these obstacles requires strategic planning and expertise.

Unpredictable site conditions, such as existing structural issues or unforeseen electrical loads, can further complicate projects. Electricians mitigate these risks through detailed site assessments and contingency planning. Collaboration with other trades is also critical to avoid conflicts and ensure seamless integration.

Efficient problem-solving, clear communication, and the use of advanced tools and techniques help overcome these challenges, ensuring the project remains on schedule and within budget.

How Can Businesses Future-Proof Their Wiring Systems for Technological Advancements?

Future-proofing wiring systems involves implementing scalable solutions that can adapt to emerging technologies. Structured cabling systems are a popular choice, offering flexibility for integrating new devices and network expansions without significant rewiring.

Provisions for renewable energy sources, such as solar panels and EV charging stations, are also becoming essential in modern commercial designs. These features not only support future needs but also contribute to sustainability goals.

Regular upgrades and maintenance, guided by professional electrical contractors like SoCal Electrical & Lighting, ensure that wiring systems remain efficient and ready for evolving demands. Call us at 760-699-2686 for expert guidance on future-proofing your wiring systems.